MIL-DTL-24416C(SH)

4.5.4 Functional test. A functional test shall be performed to demonstrate the reliability and proper functioning

of all pressure switches, shut-off devices interface, alarm system interface, visual indicators, mechanical or

pneumatic actuating mechanism, remote actuating device, fusible links, cable release system, discharge valves,

expellant gas assembly (where installed), and discharge nozzles to meet the requirements of 3.4 and 3.5. Each

extinguishing system actuation method shall be individually tested. Failure of installed wet chemical system to meet

requirements of 3.4 and 3.5 of this specification shall constitute failure of the functional test.

4.5.5 Hydrostatic test. Conformance to 3.4.2.3 shall be determined by inspection of hydrostatic pressure rating

test date in accordance with A-A-59666 or ASME Boiler and Pressure Vessel Code Section VIII as applicable (see

3.4.2.3).

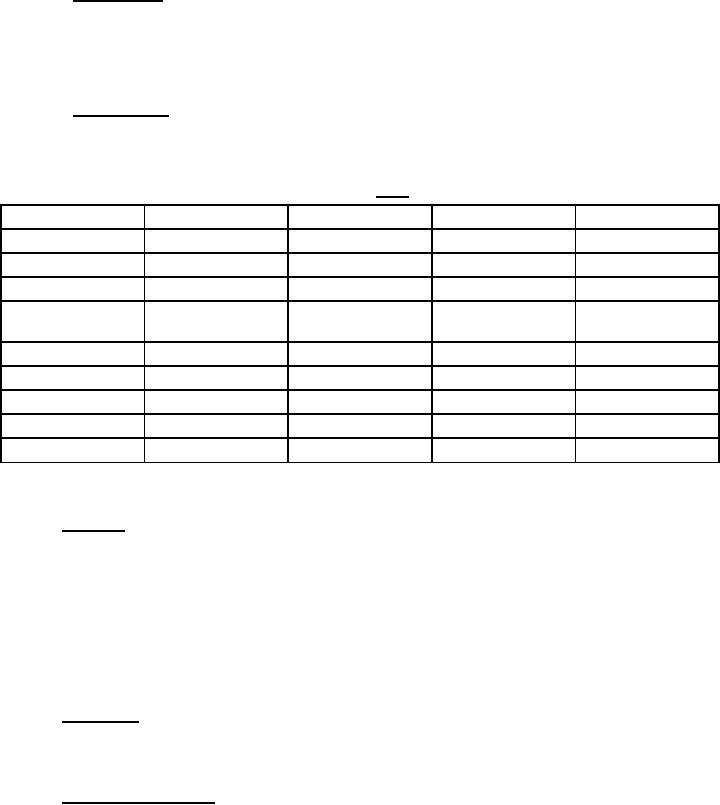

TABLE I. Tests.

Characteristic

Requirement

Test

First article

Conformance

Material

3.2 & 3.3.2

4.4, 4.5.1

X

X

Shock

3.3.3

4.5.2

X

Vibration

3.3.4

4.5.3

X

Design and

3.3.1, 3.4 3.4.2.2

4.4

X

X

construction

& 3.4.2.4 3.4.15

Hydrostatic

3.4.2.3

4.5.5

X

X

Performance

3.3.1, 3.4, & 3.5

4.5.4

X

UL certification

3.6

4.4

X

X

Workmanship

3.7

4.4

X

X

Markings

3.8

4.4

X

X

5. PACKAGING

5.1 Packaging. For acquisition purposes, the packaging requirements shall be as specified in the contract or

order (see 6.2.h). When packaging of materiel is to be performed by DoD or in-house contractor personnel, these

personnel need to contact the responsible packaging activity to ascertain packaging requirements. Packaging

requirements are maintained by the Inventory Control Point's packaging activities within the Military Service or

Defense Agency, or within the military service's system commands. Packaging data retrieval is available from the

managing Military Department's or Defense Agency's automated packaging files, CD-ROM products, or by

contacting the responsible packaging activity.

6. NOTES

(This section contains information of a general or explanatory nature that may be helpful, but is not mandatory.)

6.1 Intended use. Pre-engineered wet chemical systems are intended for protection of deep fat fryers and

doughnut fryers. A pre-engineered system has predetermined flow rates, nozzle pressures, and quantities of

extinguishing agent. These systems have the specific pipe size, maximum and minimum pipe lengths, pie volumes,

number of fittings, and number and types of nozzles approved by a testing laboratory.

6.2 Acquisition requirements. Acquisition documents should specify the following:

a.

Title, number, and date of the specification.

b.

When first article is required (see 3.1).

c.

When manufacturer's dimensional requirements for system installation and operation are not required (see

3.4).

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business